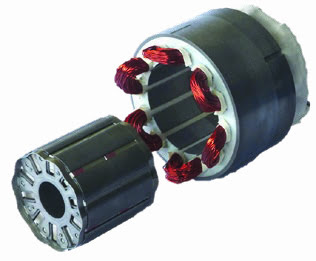

What is a kit motor?

A motor kit is an electric motor supplied without housing or bearingsmainly composed of stator and rotor.

Unlike standard "off-the-shelf" motors, the kit motor is designed to be integrated directly into a machine or system.

👉 It's a motor "to assemble" in your machine, instead of a complete block.

👉 It's a permanent magnet synchronous motor (often brushless) optimized for direct integrationThis allows a rigid coupling with the mechanical axis and a very high power density.

The advantages of a kit motor in industry

Choosing a kit motor offers many benefits:

-

Maximum compactness no casing and direct integration = space-saving.

-

High performance high efficiency, constant torque even at low speeds.

-

Personalization Easy adaptation to specific machine geometry (industrial printers, machine tools, robots).

-

Increased reliability : no intermediate elements (couplings, bearings) → fewer losses and less maintenance.

-

Lower operating costs for greater energy efficiency and longer service life.

👉 A kit motor takes takes up less space, uses less energy and lasts longer.

👉 Oe are talking about high torque density, backlash-free integration, reduced parasitic inertia.

In which sectors should you use a kit motor?

Choosing a kit motor offers many benefits:

-

Maximum compactness no casing and direct integration = space-saving.

-

High performance high efficiency, constant torque even at low speeds.

-

Personalization Easy adaptation to specific machine geometry (industrial printers, machine tools, robots).

-

Increased reliability : no intermediate elements (couplings, bearings) → fewer losses and less maintenance.

-

Lower operating costs for greater energy efficiency and longer service life.

👉 A kit motor takes takes up less space, uses less energy and lasts longer.

👉 We're talking about high torque density, backlash-free integration, reduced parasitic inertia.

Limits and points of vigilance

Although very powerful, kit motors require certain precautions:

-

Meticulous mechanical integration the user must supply the housing and bearings → requires good mechanical expertise.

-

Suitable cooling system Depending on power output, air or water cooling may be required.

-

Specific electronic control : often associated with dedicated controllers or drivers to fully exploit their performance.

-

Initial integration cost slightly higher than standard motors, but offset by performance gains.

👉 It's important to know that it's not not a plug & play motor → it requires a little more engineering.

👉 It's important to anticipate thermal constraints, dynamic balancing and drive compatibility.

A choice focused on the industrial future

Opt for a motor kitis to choose a solution modern, compact and powerful to meet the demands of high-tech industries.

Whether you are novice and you're looking for a space- and energy-saving solution, or expert for maximum precision and efficiency, the kit motor has established itself as a a strategic ally for your industrial machines.

👉 With the transition to smarter, more energy-efficient equipment, the kit engine represents a key alternative to improve plant competitiveness and sustainability.