- Introduction to variable speed control

- What is a variable speed drive and why is it essential in industry?

- Technical criteria for choosing the right variable speed drive

- Examples of concrete applications

- Adapting the variable speed drive to your sector of activity

- Anticipating maintenance and ensuring scalability

- Discover our TECH DRIVE variable speed drives

Introduction to variable speed control

Today, variable speed drives are an essential part of modern industrial environments. Whether it's to optimize energy consumption, improve process precision or extend machine life, variable speed drives play a central role. But with so many different models to choose from, how do you select the one that best suits your needs? This article offers a clear guide to help both novices and experts in their choice, taking into account the specific features of different industrial sectors.

What is a variable speed drive and why is it essential in industry?

An industrial variable speed drive (also known as a variable frequency drive) is an electronic device that controls the speed and torque of an electric motor. It plays a strategic role in modernizing production lines:

Reduced energy costs: up to 30 % savings thanks to adaptation of actual motor speed to requirements.

Improved machine life: soft start-up, reduced mechanical shocks and optimized work cycles.

Flexibility and precision: real-time adaptation of speed to meet industrial process requirements.

👉 Example: in the wiringIt ensures constant coil voltage. In the plastics processingIt precisely regulates extruder speed.

Technical criteria for choosing the right variable speed drive

Before selecting a drive, it is essential to analyze several parameters:

- Motor power and current The drive must be sized according to the rated power (kW/HP) and current input.

- Load type :

- Constant load (pumps, fans).

- Variable load (conveyors, extruders).

- High inertia loads (test benches, presses, heavy machinery).

- Power supply 230 V single-phase or 400 V three-phase.

- Environmental conditions dust, humidity, heat → choose the right protection rating (IP20, IP55, IP65).

- Integrated functions :

- Vector control for greater precision.

- Industrial communication (Modbus, Profibus, Profinet, Ethernet/IP).

- Integrated safety (STO function - Safe Torque Off).

👉 Case in point: a variable speed drive for printing should give priority to precision and regularity of speed, while a variable speed drive for the metalworking must support heavy, continuous loads.

Adapting the variable speed drive to your sector of activity

Each industrial sector has its own specific requirements. Here are some recommendations:

- Test benches high-performance inverter, torque control and the ability to simulate different load scenarios.

- Wiring Perfect motor synchronization to avoid cable breakage or twisting.

- Printing Variable speed drive guarantees constant, precise speed for impeccable results.

- Metallurgy Robust drive, capable of handling intensive loads and extended cycles.

- Plastics processing (extruders, presses) Variable speed drive with precise torque control, designed for continuous operation.

- Special machines A customized, scalable, communicating solution for integration into complex processes.

Anticipating maintenance and ensuring scalability

Choosing an inverter is not just a matter of comparing technical features. You also need to consider the longevity of your investment:

- Technical support and spare parts : choose manufacturers offering responsive after-sales service.

- Software updates to take advantage of the latest features.

- Compatibility with your PLCs and networks A well-documented, open drive avoids additional integration costs.

- Scalability Think about your future needs (line extensions, new loads, increased automation).

👉 In short, a well-chosen drive is a lever for productivity, reliability and energy efficiency in any industrial sector.

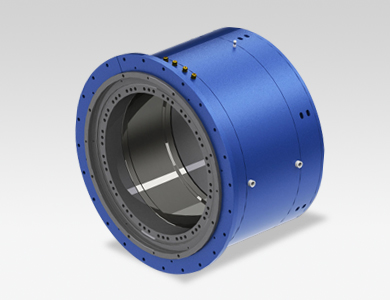

Discover our TECH DRIVE variable speed drives

Would you like to equip your installations with high-performance, reliable drives tailored to your needs?

👉 Explore our range of Parker Hannifin industrial variable speed drives & ABB industrial variable speed drives and find the ideal solution to optimize your processes.